of our company

contract production

With the REVISION D2 particle size and shape analyzer, we are confident in the particle size of our permanent paint.

Pigments are created from ecologically pure pigments raw materials for cosmetic purposes and are crushed from 38-40 to 2-4 micron.

AS COMPANY produces exactly permanent paint, that is, temporary. This paint is broken down independently in the body due to its minimal size, leaving no undesirable shades.

The particle size depends on:

origin of pigment

method of obtaining

forced size reduction using an industrial mill.

The particle size of the dye from other manufacturers is 38-40 microns

The Particle size of dye "AS COMPANY" 2-4 microns

The industrial mill in our production is a device for grinding dyes. A very fine fraction of the final product allows you to achieve ideal dye grinding of 2-4 microns.

AS COMPANY - is the only company in Russia that has achieved such a result in the grinding of dyes.

Homogenization is a process in which substances in a fluid are ground and evenly distributed throughout the volume of this medium and is necessary so that the initial fraction does not separate and the uniformity of the dye is maintained.

Silica (silicon dioxide) - silky powder of natural origin.

It is used to improve the quality and consistency of pigment. One of the main advantages is that with the addition of silica to the pigment, its light fastness increases. due to which the color saturation of the pigment is not lost and does not fade under the influence of external environmental factors

We don't need to addsurfactant, biologically active additives, and polysaccharides. We have a mechanical process for making dye without chemical intervention.

The composition of our pigments includes:

- Glycerin

- Ecusil

- Propylene Glycol

- Dipropylene Glycol

- Alcohol

- Chamomile Extract

- Water

- Silica

The advantages of our technique are ideally fine grinding of the pigment. which allows the due to easily enter the skin and linger in it and also come out easily.

Pigment production

Pigment production Video tutorial

Video tutorial  NEW

NEW AS PIGMENTS

AS PIGMENTS OPIUM COLORS

OPIUM COLORS OPIUM LIGHT

OPIUM LIGHT AREOLA / CAMOUFLAGE

AREOLA / CAMOUFLAGE Sets of pigments

Sets of pigments Cooling creams and gels

Cooling creams and gels Removers

Removers Cartridges

Cartridges Care products

Care products Pre-drawing tools

Pre-drawing tools Related products

Related products Soap with disinfectant effects

Soap with disinfectant effects PMU Devices

PMU Devices AS company products

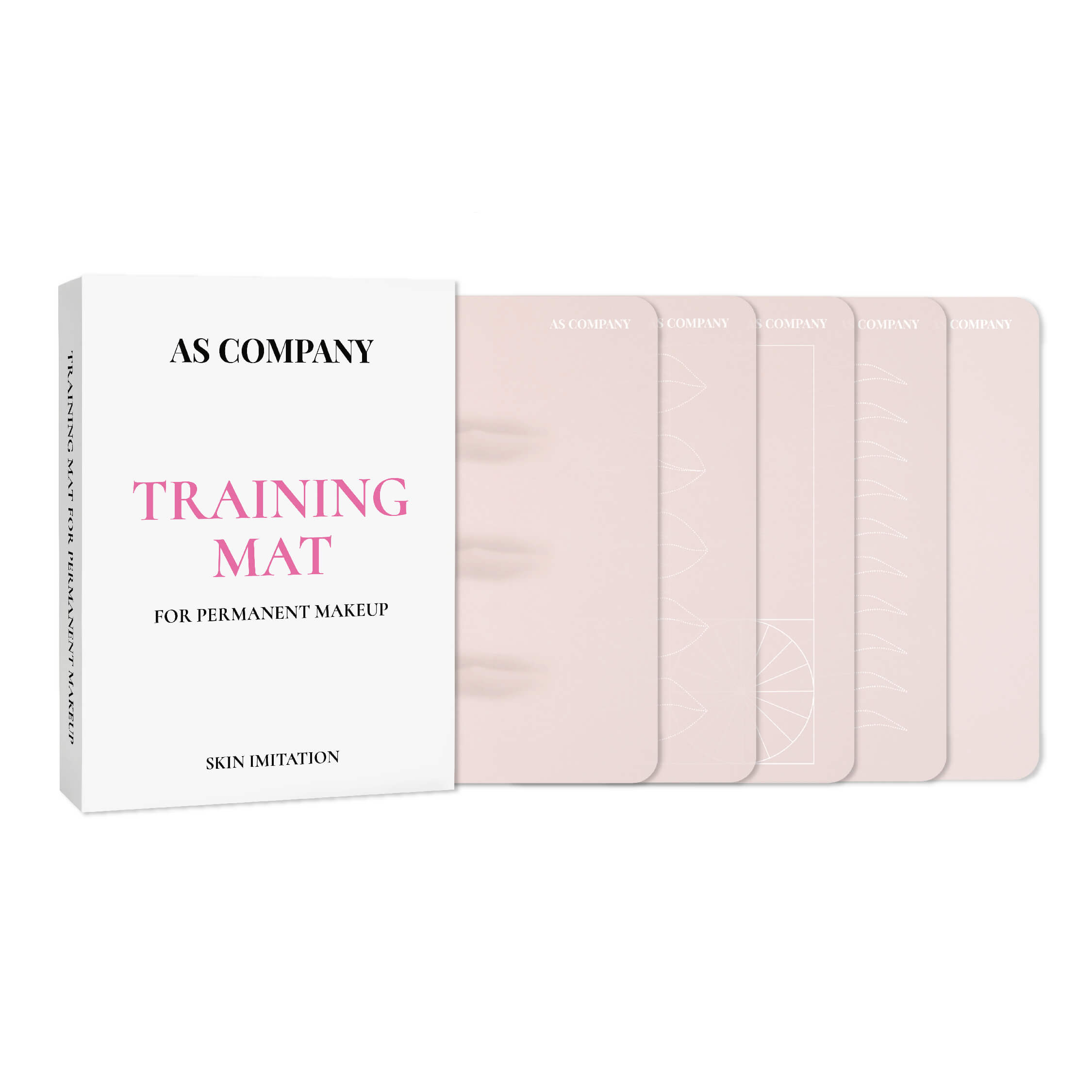

AS company products Traning Mat

Traning Mat